Composition

2 x Aluminium protected; 2 x Foam; 1 x PET Metalized

Main Applications

Suitable use in: Roofs and floors

Composition

2 x Aluminium protected; 2 x Foam; 1 x PET Metalized

Main Applications

Suitable use in: Roofs and floors

| Thickness (mm) | 5 covers |

| Presentation – (m2) | 20 |

| Length x width (m) | 16.7 x 1.20 |

| Weight (g/m2) | 279 |

| Emission factor (%) | 5 |

| Thermal Resistance | 1.47 m2 K/w |

| Reflectance (%) | 95 |

| Thermal conductivity (W/mk) | 0.012 |

| Maximum compression (kg/m2) | - |

| Acoustic reduction (db) | - |

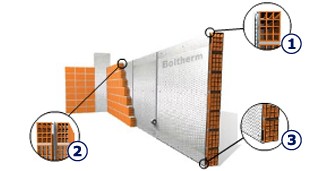

The appropriate treatment of the covers is one of the most important steps to ensure the thermal efficiency of buildings. The process of boltherm insulation goes against heat transfer: – for radiation, which is an essential component of energy transferred through the covers (particularly in summer, when you can get up to 93%); – by conduction and convection, due to the air bubble in the material and the process of assembling, with dual air box (2 cm deep, at least).

1. application of Boltherm retractor

2. application of continuous Boltherm with air box

3. application of second wall with air box

1.232 Boltherm | PVC Retractor

2. Detail of the finishing application in double air box

3. finishing Details of the application of Boltherm on the inside

The treatment of thermal bridges can make a difference in the correct insulation of buildings. For your flexibility and dimensions, the Boltherm products guarantee continuity of insulation, skirting all the building elements (beams, pillars, curved walls or irregularities, ...) and fixing the thermal bridges. The maintenance of air boxes (2 cm deep, at least) is an integral part of the Assembly process and the efficiency of Boltherm solutions.

1. application of Boltherm retractor

2. application of continuous Boltherm with air box

3. application of second wall with air box

1.232 Boltherm | PVC Retractor

2. Detail of the finishing application in double air box

3. finishing Details of the application of Boltherm on the inside